Intelligent canning factory

The company takes Industry 4.0 as the overall idea, "exploring the potential of resource energy conservation and improving the level of green manufacturing" as the concept, and combines the process characteristics of the canning industry to make unremitting efforts to achieve the goal of intelligent canning. We fully utilize advanced technologies such as RFID, high-frequency induction, soft switches, intelligent systems, servo control, and perception recognition to develop a new generation of low-carbon canning workshop technology system and solutions for green canning environments. With the help of Internet technology transfer, the digital remote temporary control and energy efficiency control technology research of the can making equipment are realized, the energy efficiency dynamics of the production process are overcome, ubiquitous perception and lean control are achieved, breakthroughs are made to varying degrees in automation, performance stability, flexible adaptability, production efficiency and other aspects, and the intelligent intercommunication management mode between the Xinqing Company and the can making manufacturers is realized.

The intelligent canning system in the future Industry 4.0 environment will bring us infinite possibilities, and Xinqing Company will work hand in hand with canning manufacturers to make progress.

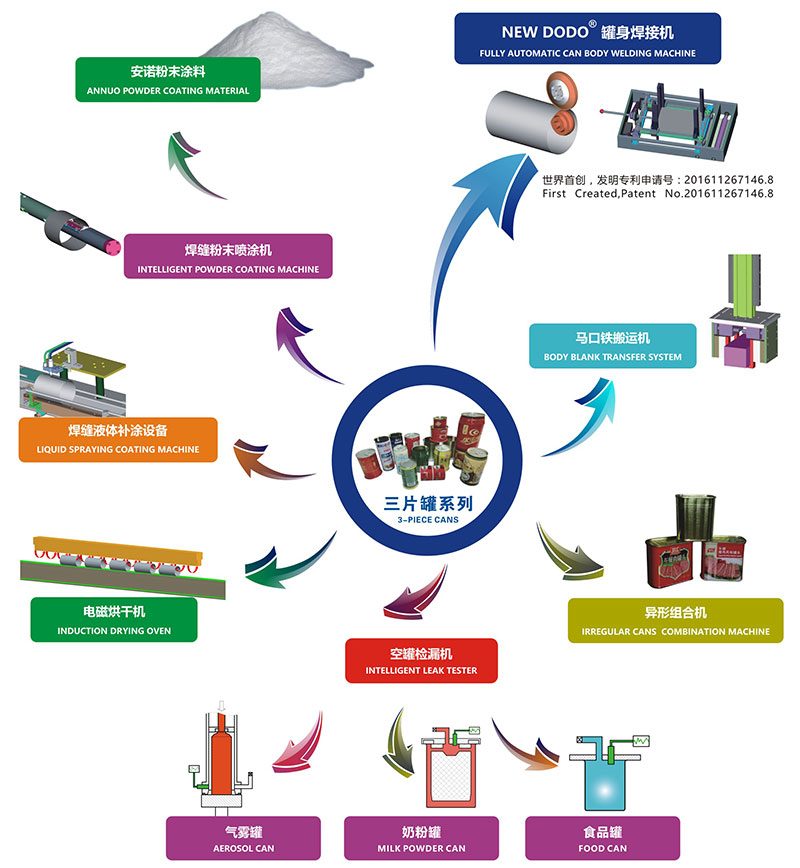

Deepen the field of three piece cans

With the continuous improvement of canning requirements, our company has successively developed and produced canning equipment such as fully automatic tinplate handling machines, fully automatic powder spraying machines, high-speed intelligent resistance welding can body welding machines, energy-saving electromagnetic induction drying machines, and fully automatic metal can leak detection machines. We have delivered and received unanimous praise from a wide range of users.

Our company will continue to deepen research on three piece can production equipment, pursue the development of faster and higher performance equipment, respond to the increasing requirements of can making, and deepen the optimization of various can making processes; Provide personalized customization according to customer needs.

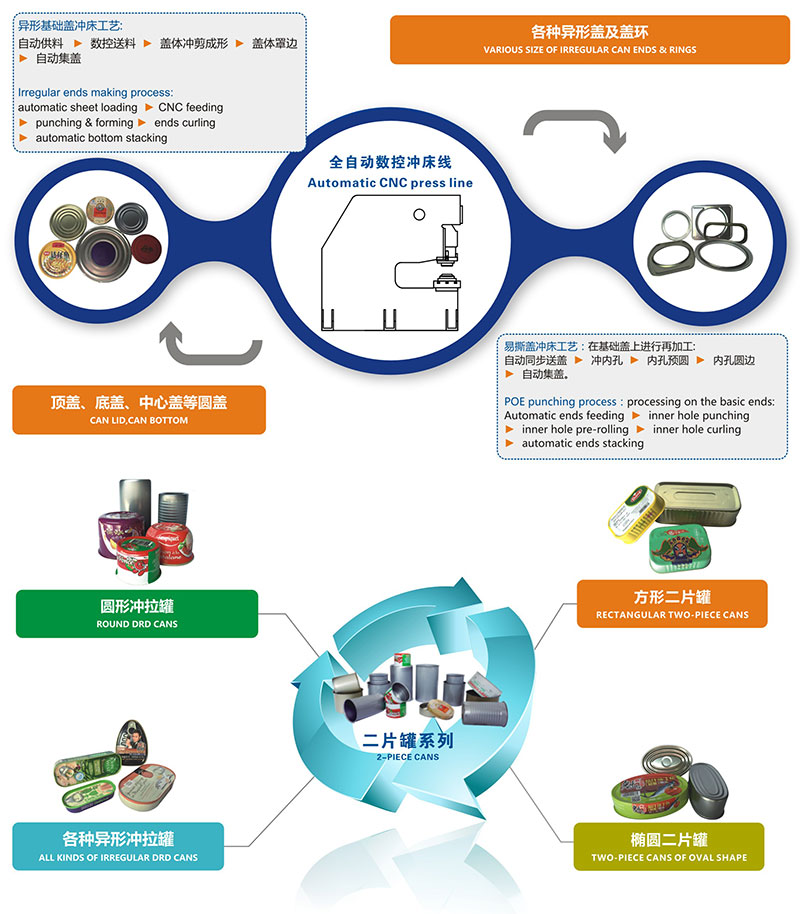

Develop personalized two-piece can production equipment

Due to the complex production process of the three piece can, there are too many nodes that need to be controlled. In recent years, the use of laminated iron and laminated aluminum stamping and drawing into two-piece cans has emerged, with a relatively simple production process that relies on stamping and forming, eliminating processes such as welding, touch up coating, drying, and sealing the bottom cover; Film coated iron and film coated aluminum have excellent performance in food safety, completely avoiding the risks faced by traditional metal cans such as bisphenol A, melamine, plasticizers, formaldehyde, etc. From materials to processes, the occurrence of food safety risks can be avoided. Two piece cans will become the new darling of the future metal packaging market.

Shantou Xinglian CNC Co., Ltd., a subsidiary of Shantou Xinqing Can Machine Co., Ltd., is committed to the research and production of two-piece can punching and pulling equipment. The equipment has the characteristics of high efficiency, low failure, intelligence, and manual safety, and is suitable for producing various round cans, square cans, and elliptical cans; According to actual production capacity requirements, single or multiple channels can be customized.

粵公網(wǎng)安備:44051102000566號 粵ICP備19094376號-1

粵公網(wǎng)安備:44051102000566號 粵ICP備19094376號-1